Last Generation Technology

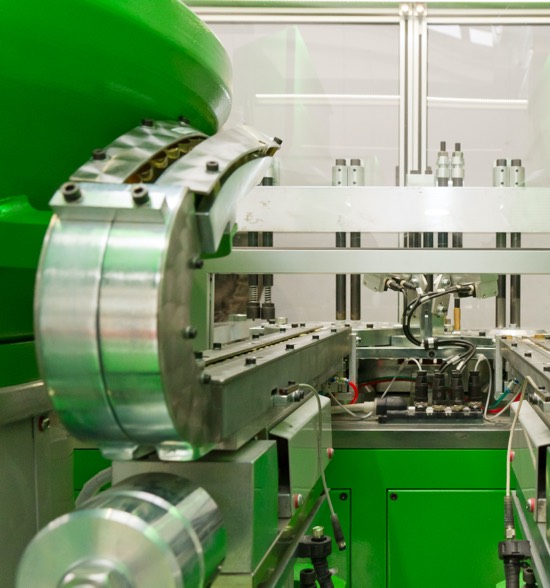

BIOAMMO has the most modern cartridge factory in Europe, with the latest machinery and technology, as well as a unique and innovative manufacturing process.

BIOAMMO’s wads and cases are designed, manufactured and assembled in-house for use in all of our nine product types.

The entire production process is monitored with strict quality controls during the four phases of cartridge manufacturing: Component production, loading, assembly and the test bench. This ensures that the cartridges have consistent high quality and reliability.

All BIOAMMO cartridges are loaded with premium double base powders, made in the USA.

For those who are committed to environmental sustainability, BIOAMMO offers a complete solution to the pollution and disposal problems that traditional plastic cartridges cause to our ecosystems.

BIOAMMO wads and cases also do not generate any micro-plastics.

For the production of their cases and wads, BIOAMMO is the only manufacturer to be supplied with biopolymers that have their respective certifications guaranteeing that they are biodegradable and compostable.

Research & Development

Following many years of intense research and development in partnership with industry-leading companies and research universities, BIOAMMO now holds the exclusive global AAA patents for the use of our bioplastic material that has been specifically designed for cartridges, offering a unique combination of strength, flexibility and biodegradability .

The performance of our cartridges has also benefited from these years of R&D&I, for example with our ergonomically designed driving-wads which ensure that the shot (whether lead, steel or alloy) is ejected from the barrel with excellent ballistic efficiency and effectiveness.

The continuous R&D&I at the BIOAMMO factory is complemented by rigorous testing that is also carried out on site, constantly monitoring and improving the use and performance of our cartridges.

Our production lines also have advanced quality control systems to guarantee a premium product.

Our Biopolymers

Biopolymers are obtained from agricultural waste such as cellulose, beetroot, sugar cane, potato and corn starch. To create the biopolymers, long chains of sugars are extracted and then synthesised to obtain the raw materials used to manufacture the wads and cases.

BIOAMMO’s biopolymers are not affected by sunlight or moisture and therefore can be stored for longer periods than, for example, cartridges with water-soluble wads.

It is only when the wads and cases come into contact with living organisms such as algae, fungi and bacteria that they are then naturally biosynthesised and transformed into a fertilising biomass.

BIOAMMO’s continuous investment in R&D has enabled significant improvements to be made to the unique biopolymer formulations, for example, an increase in the elasticity of the materials to improve the performance of the cartridge in adverse environmental conditions.

Collecting used plastic cases is worthwhile, but what do you do with them when you get home? Whether you put them in the plastic recycling container or in the organic waste, they will end up in landfill where they will continue to pollute the environment as micro-plastics for hundreds of years.

Ultimately it is a fact that plastic cartridges pollute. BIOAMMO offers the complete solution to this.

Plastic cases are not usually recycled. This is partly because of the financial, fuel and energy costs of transporting them to a facility, then removing the metal heads and recycling the plastic components.

Even when recycled, it is only a short-term “solution” as, due to the limited times that plastic can be recycled, the oil-based materials will still ultimately have to be disposed of (usually in landfill) or will be burnt (to then potentially contaminate the atmosphere).

As for the plastic wads that remain scattered in the countryside, these will continue to contaminate the environment for many future generations as they gradually degrade into micro-plastics and enter the various food chains that ultimately adversely impact on us humans.